For different scenarios, we have created the "RockLite" family of products to provide diversified solutions. From raw material selection, manufacturing to recycling, the company always adheres to the environmental protection concept of "taking from nature and using in nature", the whole production chain is green and pollution-free, and the products are healthy and environmentally friendly, bringing users a safe driving experience.

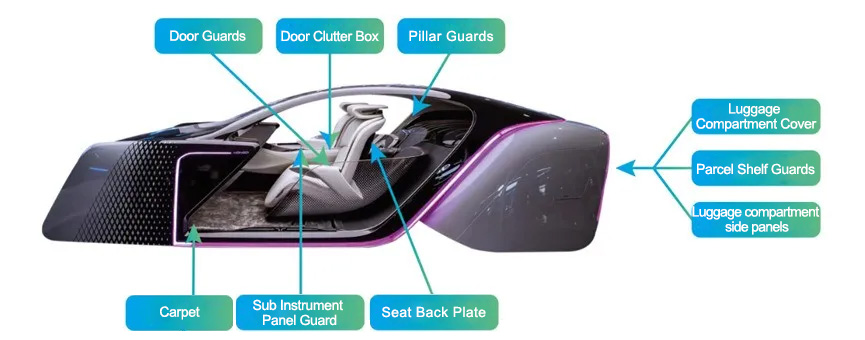

Basalt fiber composite material has excellent performance, after many rounds of optimization design and rigorous testing, has realized in the trunk lid surface protection, side surface protection, parcel shelf guard plate and other parts of the development, so that the parts to maintain the original performance based on the light weight of more than 20%, batch cost can be controlled, with large-scale application conditions.

Starting with the automotive interior guard plate, the future can be gradually expanded to the interior substrate, exterior components, single-vehicle weight reduction potential is huge. Lightweight components not only mean lower energy consumption, but also make every trip more economical and environmentally friendly.

The project takes the high-value demand of automobile industry as the traction, unites universities, material production enterprises and parts manufacturing enterprises, promotes the deep integration of innovation chain and industry chain through the cooperation mode of production, learning, research and application, realizes the integration and innovation of basalt fiber from the source end of material to the application end, and stimulates the innovation and upgrading of basalt fiber industry with the breakthrough of the industry's original common technology.